Making responsible purchasing affordable

Why don’t we make most of our products in France?

Over the last few months, many of you have asked us the same questions:

“When will you start to make your products in France? You claim to be ‘green’ but why are your clothes made on the other side of the world?”

The goal of the following explanation is not to demonstrate that our approach is better than another, but to be completely transparent about our manufacturing and distribution model, including the associated limitations and opportunities. We will also explain how we are able to make a very specific category of products in France.

Let’s start from the beginning

Since the brand’s creation in 2008, Picture has always sought to make responsible purchasing affordable. We want to reach as many people as possible, especially a large part of the general public that is not actively engaged in the environmental movement.

To make responsible purchasing affordable and the standard, we need to price our products within the range of what the market considers “the norm.”

To compare to other markets, there are hybrid or electric cars in the automobile industry but as along as they continue to be more expensive than gas- fueled cars, we cannot really claim that this “responsible” automobile purchase is affordable. Then, green vehicles will remain a niche market, only available to those with money.

The garment industry is in exactly the same situation. At Picture, we want an eco-designed jacket to cost the consumer the same amount as a regular jacket.

With this premise as our starting point, what can we do to make a responsible purchase affordable?

When we launched the brand, our distribution strategy was to work with independent shops and be viewed as an alternative to the major boardsports brands.

The culture and history of our industry (ski, snowboard, surf, and skateboard) have a strong and direct link to physical stores and online shops; they build the actual coonection between brands and the end consumer.

These shops have long played an important role in the local economy and represent thousands of jobs in France and abroad. They maintain a close relationship with the consumer by providing advice and a quality service, as well as by participating in the local scene.

A new player in the action outdoor sports market in France and worldwide

Picture’s chosen distribution model allows the brand to position itself as a new leading player in the action outdoor sports market both in France and worldwide. In addition, our new designs and history combined with an environmentally-friendly approach have allowed independent shops to renew their product offering and to grow alongside us, posting an almost 100% sell-out rate of our products.

In France, Snowleader is a great example. Created in 2008, this online shop specializes in action outdoor sports and now employs 80 people in the Northern French Alps. Picture employs 56 people in its Clermont and Annecy offices.

These two success stories exist by choosing to manufacture our products abroad, primarily in Turkey and China.

Since labor costs are lower in both countries, we are able to – not always easily – purchase a finished product from a supplier, sell it to a retailer, who then sells it to you at a price similar to our competitors.

In the process, we use eco-friendly, responsible materials while working with factories that practice fair labor.

Using a simple product as an example

100%Organic cotton used to make a Picture t-shirt

A Picture t-shirt is made entirely with organic cotton. The cotton comes from Söke, a small village in Turkey. The finished product is made 100 km away in Izmir.

We purchase the t-shirt for €7 from our supplier in Turkey, sell it for €12.50 to retailers, who then sell it to you, the end consumer, for €30 to €33, VAT included.

The factory in Turkey that makes the t-shirt is our partner, Seyfeli, a model in Turkey for its labor practices. Picture started working with them right from the start in 2008.

We consider €30 to €33, VAT included, to be a fair price for a cotton t-shirt and similar to other brands in the industry who, for the most part, do not use environmentally-responsible materials. This price allows retailers and Picture to grow in spite of our respective costs: rent, salaries, taxes, customs duties, R&D in France, logistic, and operational costs. In addition, the 20% VAT in France has a considerable influence on our approach.

The current “norm” is to use regular cotton and pay 30% less; however, this is not in line with our commitment to the environment.

To sum up: 80% of a t-shirt’s value benefits the local economy.

Supplier

Value: €7

% of value creation: 20% – abroad

Use of the added: Operating costs, purchasing raw materials, employees, taxes

Brand

Value: €12.50

% of value creation: 20% – France

Use of the added: Employees, rent, taxes, logistics, R&D, operating costs, income Taxes

Retailer

Value: €24–€25

% of value creation: 40% – France

Use of the added: Employees, commercial lease, taxes, logistics, operating costs, income taxes

Value Added Tax

Value: €32–€33

% of value creation: 20% – France

Use of the added: Taxes

| Value creator | Value | % of value creation | Use of the added value |

|---|---|---|---|

| Supplier | €7 | 20% – abroad | Operating costs, purchasing raw materials, employees, taxes |

| Brand | €12.50 | 20% – France | Employees, rent, taxes, logistics, R&D, operating costs, income taxes |

| Retailer | €24–€25 | 40% – France | Employees, commercial lease, taxes, logistics, operating costs, income taxes |

| Value Added Tax | €32–€33 | 20% – France | Taxes |

And what if we made a t-shirt in France while keeping the same distribution model?

In every case, we would need to source the raw materials outside of France: most of the world’s cotton growers are in India, China, and the United States. Cotton farming does not really exist in France. Once the cotton in hand, we would then be able to spin, weave, dye, and make the product in France.

The cost of labor in France is much higher than in Turkey or China, which means that we would purchase the t-shirt from the manufacturer for €20-€25, sell it for €30-€35 to the retailer, who would then sell it to you for €70-€75 VAT included.

Only a very small number of people would be willing to pay such a high price for a t-shirt. We would stray from our goal to make responsible purchasing affordable.

What would happen if we sold this Made in France t-shirt directly to the end consumer (without a going through a shop or retailer)?

We would buy the Made in France t-shirt for the same price (€15-€20), and once we add our margin, we could sell the t-shirt at a reasonable price.

This is the chosen model for several French brands, such as Hopaal and 1083.

Clément, co-founder of Hopaal explains his approach:

“Producing locally and using recycled materials means a high production costs. This is perfectly normal since garments are difficult to make. For our line of clothing made with recycled materials, you have to first collect, separate, clean, and recycle the source materials before you can spin, weave, cut, and then make the garment. Each step of the way requires people who know how to do their job, and we pay them a proper wage.”

“The best we can do to offer customers a Made in France garment at a reasonable price is to sell them exclusively through our website, bypassing retailers.”

Where would Picture be if we had made this choice from the start?

It’s impossible to say. We think that we would only be a minor player in the boardsports clothing market, since the brand would not be present in the shops that represent the foundation of the industry and where (whether a physical or online shop) consumers go to purchase and enjoy a unique experience, one important to our market.

To conclude, we would have probably been successful in France, our home market, but not beyond. The chosen distribution model is vital to understanding where a product is made. This is a conscious choice.

However, we do make products in France in certain specific cases

2minutes to make a neck gaiter

For example, our neck gaiters are made at the Cenyo factory in Chatillon-en-Michaille, France. The polyester is sourced in Italy.

The time it takes a person to actually make a neck gaiter is quick, just 2 minutes. Add to that the time it takes to cut the material, print the motif, prepare the labels, and then package it. This allows us to sell the product at a reasonable price.

We prefer to make the product in France in this specific case, but this also means that we use conventional polyester and not polyester derived from recycled plastic bottles (the fabric that we use for neck gaiters is not available in Europe in recycled polyester).

Let’s address other remarks we hear quite often

“You claim to be environmentally responsible, but you manufacture your garments on the other side of the world.”

This represents one of the challenges that international brands face. The “other side of the world” ends up being relative when you take the Asian and Oceanic markets into consideration, markets that have a lot of potential for Picture. A garment made in China that is sold in Japan makes sense to us.

What if we made all of our products in France and then sold them in Japan? Wouldn’t it be legitimate for the Japanese to claim that our products are made on the other side of the world?

Actually, it is not as simple as that, and quite counter-intuitive.

When you look at The Environmental Impact of the Global Apparel and Footwear Industries, Quantis, 2018, transportation and distribution account for a very small part of total CO2 emissions: 1,3%.

The biggest impact is located during the manufacturing process: raw material extraction and fiber production (15%), spinning (28%), weaving/knitting (12%), dyeing and finishing (36%), then assembling (7%). End of life accounts for 0,3%.

The main notion to keep in mind is that all the stages we’ve just mentioned require energy (electrical or direct combustion) to make machines work.

If the needed energy comes from fossil fuels (coal, oil, natural gas), the impact on global warming and climate change will be very clear and consequential, no matter where something is produced.

Indeed, electricity production is the main cause of CO2 emissions in the world (40%) and energy use by industrial companies (direct combustion) accounts for 19%. Source: International Energy Agency, 2018.

It is therefore essential to have a good understanding of the energy mix of producing countries and the carbon intensity per kilowatt-hour produced.

France, for example, can be considered as a very low-carbon country as its electricity production is largely decarbonized thanks to nuclear power, which emits virtually no CO2 (life cycle analysis). In Europe, we can also mention Iceland, Albania, Norway, Switzerland, Sweden, Latvia and Portugal as countries with very low carbon emissions when it comes to electricity production.

To clarify, as soon as a country's energy mix includes a majority of renewable energies (wind, hydraulic, solar, geothermal) or very low carbon (nuclear), then we can consider, from a pure CO2 emissions perspective, that it is a very good place to have textile productions.

Check a country’s energy mixThe energy topic is crucial in the fight against global warming. It has logically become our priority. Wiping out the use of fossil fuels (coal, oil, natural gas) in favor of renewable and low carbon energies should be the world’s NUMBER ONE priority in the effort to reduce our CO2 emissions. The textile industry has no choice but to adapt.

In Taiwan, solar panels have already been installed as a way to self-power the lamination factory we work with, and a similar project is currently underway in Turkey (our cotton spinning factory) to replace a portion of the electricity coming from coal-fired power plants. Our partners in these two countries are our priority since they handle more than 80% of Picture’s overall production volume.

Even though emissions are local, their impact on the climate is global.

There is also another way to view the situation to better understand why this issue takes precedence over all others: our business inherently increases the energy needs in certain countries, making their transition to renewable and low-carbon power more complicated and costly. We are directly responsible. Making the necessary financial investment and working with other brands in the industry is the only fair, right thing to do, and will benefit everyone: even though emissions are local, their impact on the climate is global.

Presently, here is a list of our current initiatives that justify the brand’s environmentally and socially responsible position while manufacturing most if its products outside of France:

Using environmentally friendly and responsible materials (organic cotton, recycled polyester, bio-sourced polyester, reconditioned materials)

Dying processes that reduce energy and water consumption

A durable water repellent finish free of toxic chemicals

Certifications to back up the first three bullet points

A complete and thorough understanding of our supply chain, from raw materials to the finished product

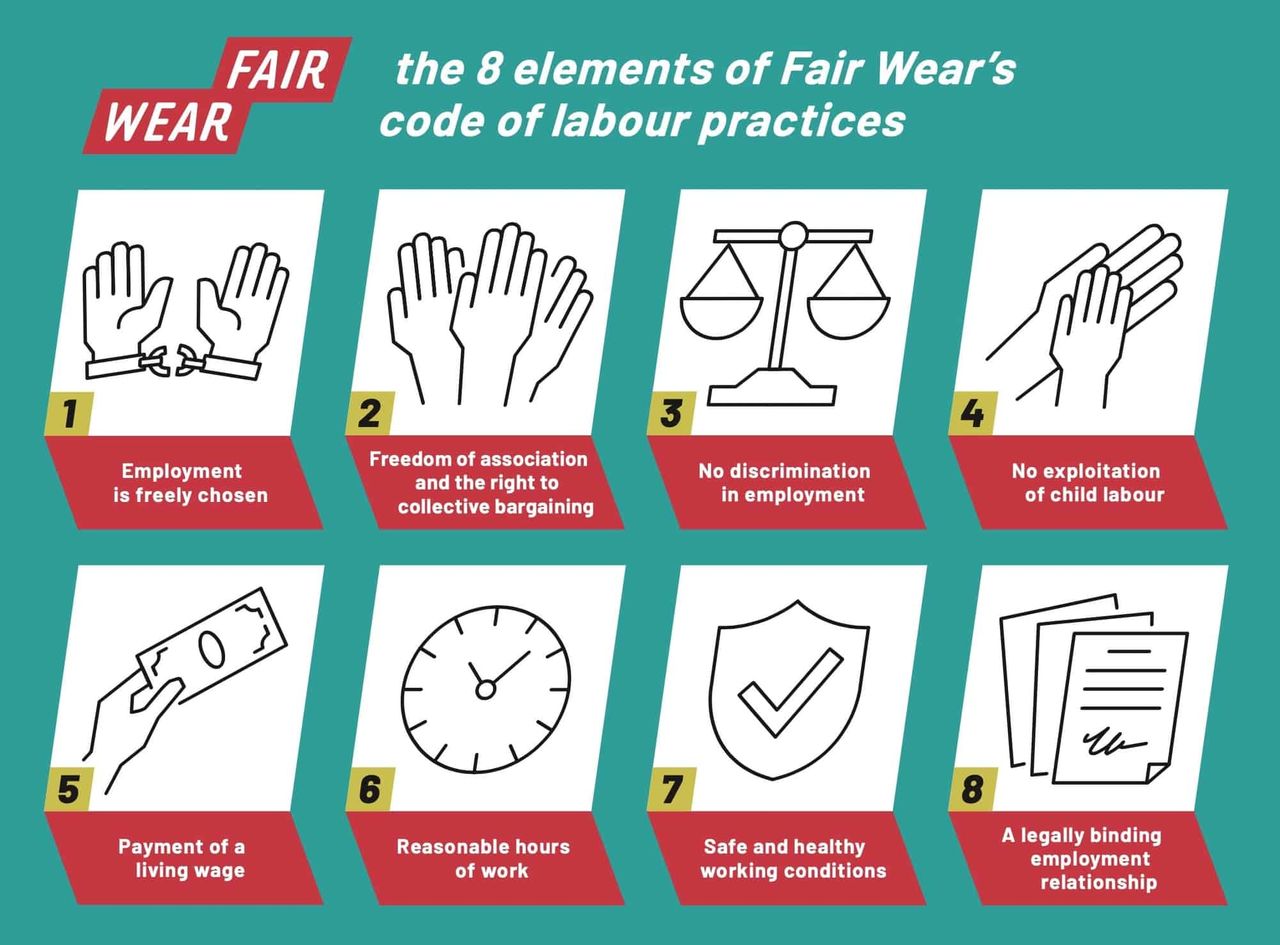

Long-term relationships with our suppliers and partnering with the Fair Wear Foundation to continuously improve workplace conditions for labor

Shipping only by boat to transport products to our warehouses, we never use air freight

A packaging policy to reduce our use of polybags as much as possible

We remain, however, far from completely satisfied with our chosen model, and we continuously work to improve each point on the list, sometimes throwing one out for something better.

We hope that this article provides you with a clear understanding of our approach, why we make most of our products outside France, and the resources required to make our garments in our home country. Nevertheless, we very much admire French brands who contribute to giving French factories a new start.